Liquid jet mixing nozzles and tank mixing systems

Ourliquid jet mixing nozzles are the main components of special mixing systems which can be applied for continuous as well as discontinuous mixing duties.

They can be used as complete replacement for mechanical agitators and in many cases they surpass their mixing results.

Working principle

Advantages of the mixing nozzles

Fields of application

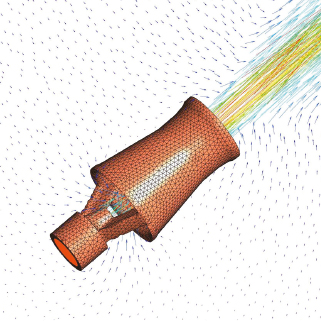

When using the Computational Fluid Dynamics (CFD) model for mixing systems some helpful simplifications are used:

- steady state modelling (not transient)

- turbulent flow modelled with of two equation turbulence model

- numerical grid with tetrahedral cells

- smooth liquid surface

- modelling of pipings and support plates, if required

- physical properties of the flow medium, e.g. fuel oil with high dynamic viscosity (up to 500 mPas)

|

Numerical set-up for a storage tank

|

Numerical flow simulation

The aim of the numerical tests carried out is an optimum arrangement of the mixing nozzles inside the tank with regard to the a.m. design strategy. The tests are based on a liquid-filled cylindrical tank.

Various combinations of flow medium and tank geometry can be optimised for customer specific tests per CFD by selecting corresponding physical material characteristics of the flow medium resp. special geometry requirements. The tank geometry to be tested is simulated by means of a CAD program. Digital geometry information of the individual mixing nozzles is imported directly from CAD systems used in the design process. Number, position and alignment of the simulated mixing nozzles inside the tank are determined, so that the complete tank configuration can be simulated digitally.

The whole simulated geometry consisting of all liquid jet mixing nozzles and the tank with pump connection is converted to a calculation grid by means of a so-called grid generator which is the basis of the CFD. The fluidic fundamental equations are solved for each of the cells generated within the grid.

Primarily, these are the conservation equations for mass, impulse and energy. Two further conservation equations will be solved in order to consider the turbulence caused by the liquids. All conservation equations are solved by means of the so-called equation resolver. In order to simplify the calculations they are based on stationary flow conditions. The whole simulation process from the grid generation up to the representation of the results takes place automatically for the most part.

On the one hand, geometrical boundary conditions for the simulation are the tank dimensions (filling height H, tank diameter D) as well as the position and size of the pump connections and on the other hand the number, position and alignment of the liquid jet mixing nozzles. Operational boundary conditions are determined by the motive pressure at the liquid jet mixing nozzle and the physical properties of the motive flow.

Examples of CFD calculation results

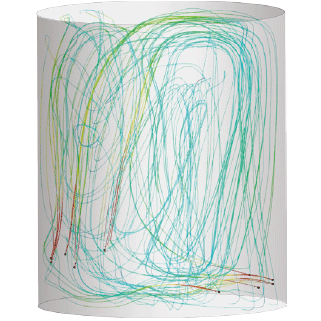

Edible oil tank

|

|

mixing nozzles: 32 x 2 Zoll tank volume: 8500 m³ motive flow rate: 790 m³/h liquid density: 910 kg/m³ liquid viscosity: 35 mPas mixing power: 5.2 W/m³ average liquid velocity: 0.17 m/s |

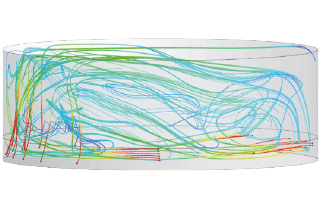

Waste water tank

|

|

mixing nozzles: 25 x 2 Zoll tank volume: 20200 m³ motive flow rate: 770 m³/h liquid density: 900 kg/m³ liquid viscosity: 50 cpoise mixing power: 4.2 W/m³ average liquid velocity: 0.09 m/s |

Fuel oil tank

|

|

tank volume: 60 m³ motive flow rate: 12.8 m³/h mixing power: 320 W/m³ average liquid velocity: 0.24 m/s |

Computational Fluid Dynamics (CFD)

IMAGE: Example of a Computational Fluid Dynamics (CFD) for an edible oil tank - optimum application without dead zones